Zvikamu zvakawanda zvemagiya matsva ekuderedza simbauyemagiya emotokaripurojekiti iyi inoda kupfurwa mushure mekukuya magiya, izvo zvinokanganisa kunaka kwezino, uye zvinotokanganisa mashandiro eNVH yesystem. Pepa iri rinoongorora kushata kwepamusoro pezino kwemamiriro akasiyana ekuita kwekupfurwa uye zvikamu zvakasiyana usati wapfurwa uye mushure mekupfurwa. Mhedzisiro yacho inoratidza kuti kupfurwa kuchawedzera kushata kwepamusoro pezino, izvo zvinokanganiswa nehunhu hwezvikamu, maparamendi ekuita kwekupfurwa nezvimwe zvinhu; Pasi pemamiriro aripo ekugadzira batch process, kushata kwepamusoro kwepamusoro kwepamusoro pezino mushure mekupfurwa kunosvika ka3.1 kupfuura usati wapfurwa. Simba rekushata kwepamusoro pezino pakushanda kweNVH rinokurukurwa, uye matanho ekuvandudza kushata mushure mekupfurwa anokurudzirwa.

Pasi pemashoko ari pamusoro apa, bepa iri rinokurukura kubva pazvinhu zvitatu zvinotevera:

Kukanganiswa kwezviyero zvekushandisa pakubaya mazino nepfuti pakuoma kwemazino;

Kukura kwekuwedzera kwekubaya mabara pamusoro pemazino pasi pemamiriro ezvinhu aripo ekugadzira mabara;

Kukanganiswa kwekuwedzera kwekukweshana kwemazino pamusoro pemazino pakushanda kweNVH uye matanho ekuvandudza kukweshana mushure mekubaya.

Kuboorwa kwepfuti kunoreva maitiro ayo mapfuti madiki akawanda ane kuomarara kwakanyanya uye kufamba nekukurumidza kunorova pamusoro pezvikamu. Pasi pekukanganiswa nekukurumidza kwebhoorwa, pamusoro pechikamu chinoburitsa makomba uye kushanduka kwepurasitiki kuchaitika. Masangano akakomberedza makomba acharamba kuchinjika uku uye anogadzira kumanikidzwa kwakasara. Kupindirana kwemakomba akawanda kuchaumba denderedzwa rakafanana rekumanikidzwa pamusoro pechikamu, nokudaro zvichivandudza simba rekuneta kwechikamu. Zvichienderana nenzira yekuwana kumhanya kukuru nepfuti, kubhoorwa kwepfuti kunowanzo kamurwa kuita kudzvanywa kwemhepo yakamanikidzwa uye kupwanywa kwepakati, sezvakaratidzwa muMufananidzo 1.

Kuboorwa kwemhepo yakamanikidzwa kunotora mweya wakamanikidzwa sesimba rekupfapfaidza pfuti kubva mupfuti; Kuboorwa kwepakati pepfuti kunoshandisa mota kufambisa impeller kuti itenderere nekumhanya kukuru kuti ipotse. Zvinhu zvakakosha zvekushandisa pakuboorwa kwepfuti zvinosanganisira simba rekuzara, kufukidzwa uye hunhu hwepakati hwekuboorwa kwepfuti (zvinhu, saizi, chimiro, kuomarara). Simba rekuzara kwepfuti iparameter inoratidza simba rekuboorwa kwepfuti, iro rinoratidzwa nekukwirira kwearc (kureva mwero wekukotama kwechikamu chebvunzo cheAlmen mushure mekuboorwa kwepfuti); Mwero wekufukidza unoreva chiyero chenzvimbo yakafukidzwa negomba mushure mekuboorwa kwepfuti kunzvimbo yese yenzvimbo yakaboorwa; Nzvimbo dzinowanzo shandiswa dzekuboorwa kwepfuti dzinosanganisira simbi yekucheka waya, cast steel shot, ceramic shot, glass shot, nezvimwewo. Saizi, chimiro uye kuoma kwenzvimbo dzekuboorwa kwepfuti dzine mamakisi akasiyana. Zvinodiwa zvemaitiro ese ezvikamu zvegear shaft zvinoratidzwa muTafura 1.

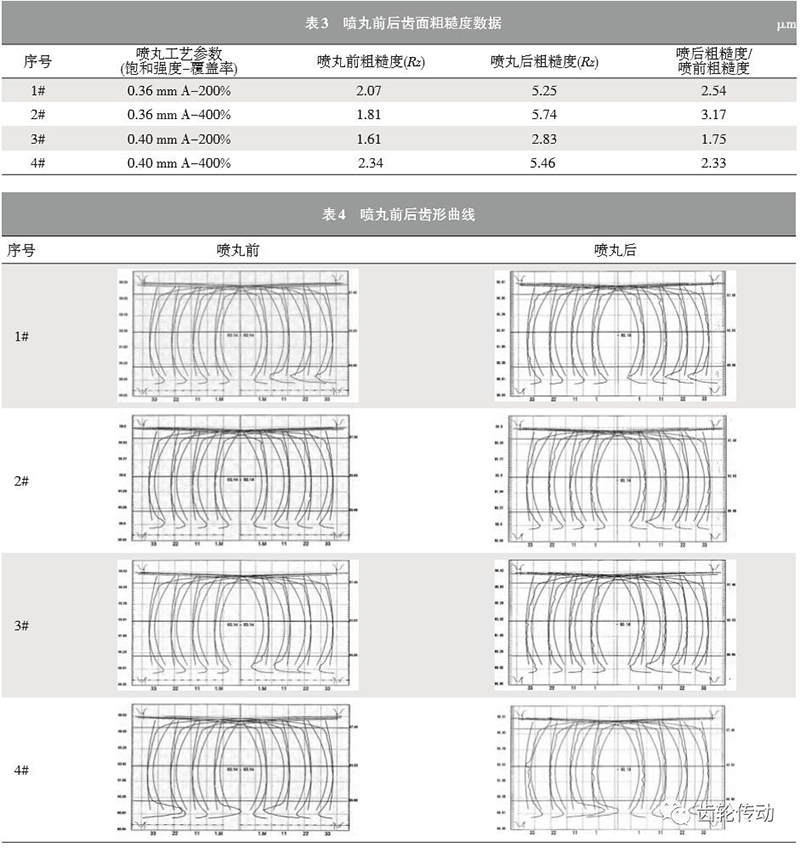

Chikamu chekuyedza ndicho giya repakati peshaft 1/6 yepurojekiti yehybrid. Chimiro chegiya chinoratidzwa muMufananidzo 2. Mushure mekukuya, chimiro chepamusoro pezino chiri Giredhi 2, kuomarara kwepamusoro kuri 710HV30, uye kudzika kwechikamu chekuomesa kunoshanda kuri 0.65mm, zvese zviri mukati mezvinodiwa zvehunyanzvi. Kuomarara kwepamusoro pezino usati wabaya kunoratidzwa muTafura 3, uye kururama kweprofile yezino kunoratidzwa muTafura 4. Zvinogona kuonekwa kuti kuomarara kwepamusoro pezino usati wabaya kumeso kwakanaka, uye kutenderera kweprofile yezino kwakatsetseka.

Chirongwa chebvunzo uye maparamita ebvunzo

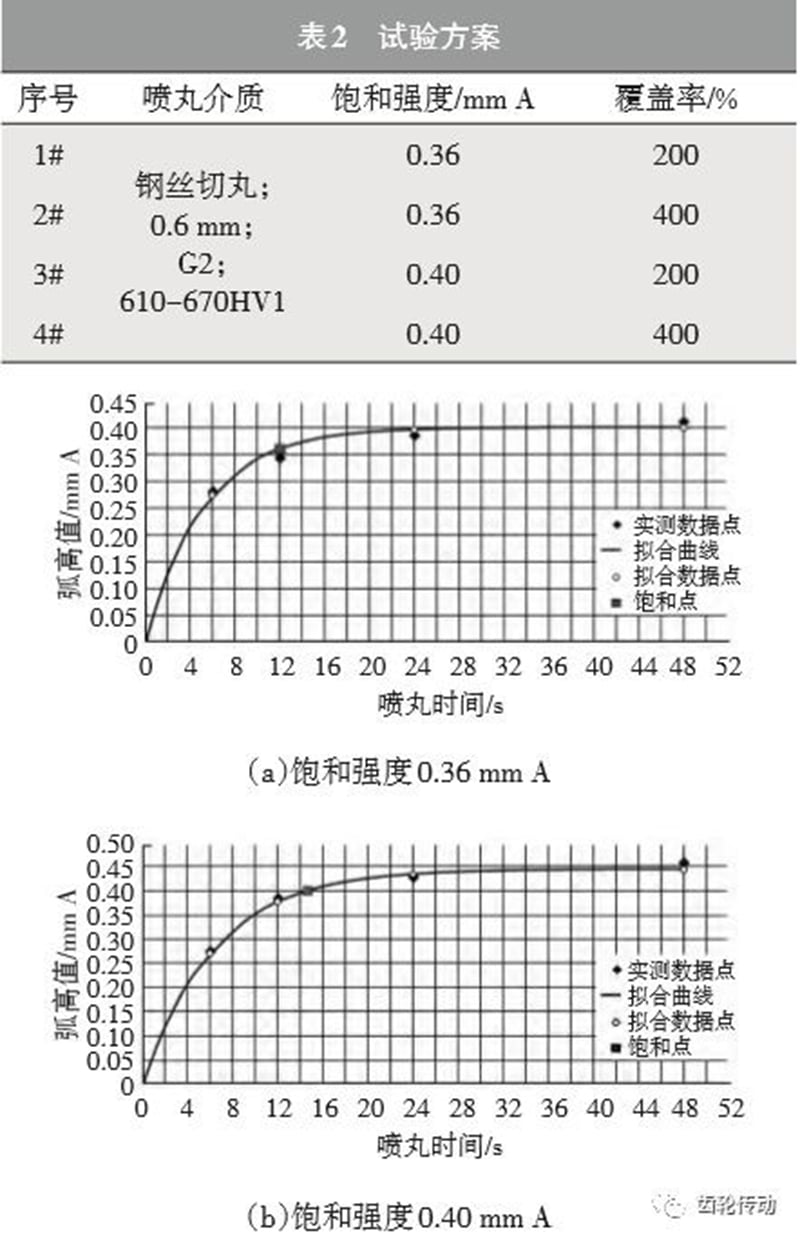

Muchina wekupinza zino wakamanikidzwa uchishandisa mhepo yakadzvanywa unoshandiswa mukuyedza. Nekuda kwemamiriro ekuyedza, hazvigoneke kuona kuti zvinhu zvepakati pezino zvakakanganiswa sei (zvinhu, saizi, kuomarara). Saka, zvinhu zvepakati pezino zvakadzvanywa zvinoenderana mukuyedza. Simba rekuzara uye kufukidza kwaro chete ndiko kunosimbiswa. Ona Tafura 2 yechirongwa chekuyedza. Maitiro chaiwo ekuona maparamita ekuyedza ndeekuti: dhirowa curve yekuzara (Mufananidzo 3) kuburikidza neAlmen coupon test kuti uone nzvimbo yekuzara, kuitira kuti uvhare kumanikidzwa kwemhepo yakadzvanywa, kuyerera kwesimbi, kumhanya kwekufamba kwenozzle, daro renozzle kubva kuzvikamu nezvimwe zviyero zvemidziyo.

mhedzisiro yebvunzo

Ruzivo rwekuoma kwemazino mushure mekubaya zino runoratidzwa muTafura 3, uye kururama kweprofile yemazino kunoratidzwa muTafura 4. Zvinogona kuonekwa kuti pasi pemamiriro mana ekubaya zino, kuoma kwepamusoro pezino kunowedzera uye curve yeprofile yemazino inova yakakombama uye yakakombama mushure mekubaya zino. Chiyero chekuoma kwemazino mushure mekupfapfaidza nekuoma kwemazino usati wapfapfaidza chinoshandiswa kuratidza kukura kweoma (Tafura 3). Zvinogona kuonekwa kuti kukura kweoma kwakasiyana pasi pemamiriro mana ekuita.

Kutevera Kukura Kwemazino Nekutsvuka Kwemazamu Nekupfura Nemabara

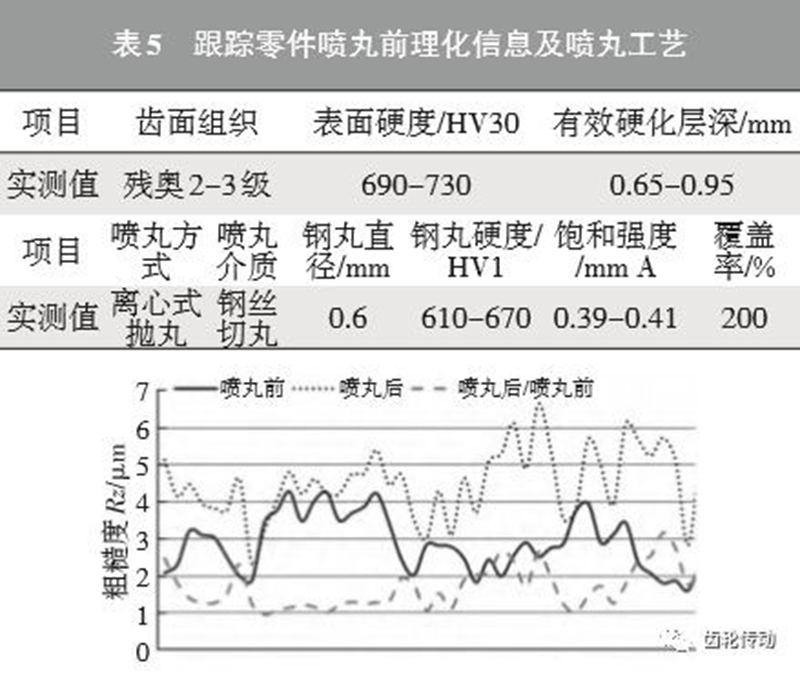

Mhedzisiro yebvunzo muChikamu 3 inoratidza kuti kuomarara kwepamusoro pezino kunowedzera nematanho akasiyana mushure mekubuda kwebvudzi nemagadzirirwo akasiyana. Kuti tinzwisise zvizere kuwedzera kwekubuda kwebvudzi paganda repamusoro pezino uye kuwedzera huwandu hwemasampuli, zvinhu zvishanu, mhando shanu uye zvikamu makumi mana nemana zvese, zvakasarudzwa kuti zvitevedzere kuomarara pamberi uye mushure mekubuda kwebvudzi pasi pemamiriro ekugadzirwa kwebatch shot peeping process. Ona Tafura 5 yeruzivo rwepanyama uye rwemakemikari uye ruzivo rwekubuda kwebvudzi pazvikamu zvakateverwa mushure mekukuya giya. Kuomarara uye kukura kwenzvimbo dzepamberi nedzekumashure dzezino risati rabuda kunoratidzwa muMufananidzo 4. Mufananidzo 4 unoratidza kuti huwandu hwekuomarara kwepamusoro pezino risati rabuda kupfura iRz1.6 μ m-Rz4.3 μ m; Mushure mekubuda kwebvudzi, kuomarara kunowedzera, uye huwandu hwekugoverwa iRz2.3 μ m-Rz6.7 μ m; Kuomarara kwakanyanya kunogona kuwedzerwa kusvika ka3.1 usati wabuda.

Zvinokonzera kukwesha kwemazino mushure mekubaya

Zvinogona kuonekwa kubva papfungwa yekubaya pfuti kuti kuomarara kwakanyanya uye kupfura kunofamba nekukurumidza kunosiya makomba asingaverengeki pamusoro pechikamu, izvo zvinova manyuko ekumanikidzwa kwakasara. Panguva imwe chete, makomba aya anosungirwa kuwedzera kuomarara kwepamusoro. Hunhu hwezvikamu zvisati zvabaya pfuti uye maparamendi ekuita kwekubiridzira pfuti zvinokanganisa kuomarara mushure mekubaya pfuti, sezvakanyorwa muTafura 6. MuChikamu 3 chepepa rino, pasi pemamiriro mana ekuita, kuomarara kwepamusoro pezino mushure mekubaya pfuti kunowedzera kusvika padanho rakasiyana. Muyedzo uyu, kune zvinhu zviviri zvinochinja, zvinoti, kuomarara kwepamberi pekubaya pfuti uye maparamendi ekuita (simba rekuzara kana kufukidza), izvo zvisingakwanise kunyatsoona hukama huripo pakati pekubaya pfuti mushure mekubaya pfuti uye chimwe nechimwe chinhu chinopesvedzera. Parizvino, nyanzvi dzakawanda dzakaita tsvakiridzo pane izvi, uye dzakaisa muenzaniso wekufanotaura kwekushomeka kwepamusoro mushure mekubaya pfuti zvichibva pane simulation yechinhu chakaganhurirwa, iyo inoshandiswa kufanotaura kukosha kwekushomeka kunoenderana kwemaitiro akasiyana ekubaya pfuti.

Zvichibva pane zvakaitika chaizvo uye tsvakiridzo yevamwe nyanzvi, nzira dzesimba rezvinhu zvakasiyana-siyana dzinogona kufungidzirwa sezvakaratidzwa muTafura 6. Zvinogona kuonekwa kuti kuomarara mushure mekuboora kunokanganiswa zvizere nezvinhu zvakawanda, izvo zviriwo zvinhu zvikuru zvinokanganisa kushushikana kwekusara kweboora. Kuti kuderedze kuomarara mushure mekuboora kweboora pachifungwa chekuti pane kushushikana kwekusara kweboora, nhamba yakawanda yemiedzo yemaitiro inodiwa kuti nguva dzose kuwedzere kunaka kwemusanganiswa wemaparameter.

Kukanganiswa kwemazino pamusoro pemazino pakushanda kweNVH kwehurongwa

Zvikamu zvegiya zviri mu dynamic transmission system, uye kuomarara kwemusoro wezino kuchakanganisa mashandiro azvo eNVH. Mhedzisiro yekuyedza inoratidza kuti pasi pemutoro nekumhanya kwakafanana, kuomarara kwemusoro, kudedera nekunzwika kwemuchina wacho kunowedzera; Kana mutoro nekumhanya zvichiwedzera, kudedera nekunzwika kunowedzera zviri pachena.

Mumakore achangopfuura, mapurojekiti ezvidzikisi zvitsva zvesimba akawedzera nekukurumidza, uye anoratidza mafambiro ekukura kwekukurumidza kukuru uye torque yakakura. Parizvino, torque yepamusoro yemudzikisi wedu mutsva wesimba i354N · m, uye kumhanya kwepamusoro i16000r/min, iyo ichawedzerwa kusvika kupfuura 20000r/min mune ramangwana. Mumamiriro ezvinhu akadaro ekushanda, pesvedzero yekuwedzera kwekuoma kwemazino pakushanda kweNVH kwesystem inofanira kufungwa nezvayo.

Matanho ekuvandudza kukwesha kwemazino mushure mekubaya

Maitiro ekubaya zino mushure mekukuya giya anogona kuvandudza simba rekubaya zino regiya uye simba rekukombama kwemudzi wezino. Kana maitiro aya achifanira kushandiswa nekuda kwezvikonzero zvesimba mukugadzirwa kwegiya, kuitira kufunga nezvekushanda kweNVH kwesystem, kuomarara kwepamusoro pegiya zino mushure mekubaya zino kunogona kuvandudzwa kubva pazvinhu zvinotevera:

a. Gadzirisa maparamita ekuita kuti zino ribude pachena mushure mekubuda pachena, uye dzora kuwedzera kwekuoma kwemazino mushure mekubuda pachena uchitarisira kuti mazino arambe aripo. Izvi zvinoda bvunzo dzakawanda dzekuita, uye kugona kwacho hakuna kusimba.

b. Maitiro ekugadzira mabara akagadzirwa nesimbi anoshandiswa, kureva kuti, mushure mekunge simba rekushandisa mabara rapera, rimwezve basa rekugadzira mabara rinowedzerwa. Simba rekushandisa mabara rakawedzerwa rinowanzova diki. Rudzi nehukuru hwezvinhu zvinogadzirwa nemabara zvinogona kugadziriswa, zvakaita seceramic shot, glass shot kana steel wire cut shot ine saizi diki.

c. Mushure mekubaya mazino, maitiro akadai sekupukuta mazino uye kukwenenzverwa kwemazino anowedzerwa.

Mupepa rino, kushata kwemazino emhando dzakasiyana dzemabatirwo ekubuda kwemazino nezvikamu zvakasiyana-siyana zvisati zvaitika uye mushure mekubuda kwemazino, uye mhedziso dzinotevera dzinotorwa zvichibva pamabhuku:

◆ Kuboora mazino nepfuti kunowedzera kuomarara kwemazino, izvo zvinokanganiswa nehunhu hwezvikamu zvisati zvaboora mazino, maparamendi ekuita kuti zino riboore pamwe nezvimwe zvinhu, uye izvi zvinhu zvikuru zvinokanganisa kumanikidzwa kwasara kwemazino;

◆ Pasi pemamiriro ezvinhu aripo ekugadzira batch, kuomarara kwepamusoro pezino mushure mekubaya zino kwakapetwa katatu nehafu kupfuura usati wabaya zino;

◆ Kuwedzera kwekuoma kwemazino pamusoro pemazino kuchawedzera kudedera uye ruzha rwesisitimu. Kana torque nekumhanya kwakanyanya, kuwedzera kwekudedera uye ruzha kuri pachena;

◆ Kuoma kwemazino mushure mekubuda kwebvudzi kunogona kuvandudzwa nekuvandudza maparamita ekuita kuti bvudzi ribude, kuburitsa bvudzi rakasanganiswa, kuwedzera kupukuta kana kukwenenzverwa kwebvudzi mushure mekubuda kwebvudzi, nezvimwewo. Kugadziriswa kwemaparamita ekuita kuti bvudzi ribude zvakanaka kunotarisirwa kudzora kuwedzera kwebvudzi kusvika kanenge ka1.5.

Nguva yekutumira: Mbudzi-04-2022