GiyaKugadziriswa kweprofile yemazino chinhu chakakosha pakugadzira giya, zvichivandudza mashandiro azvo nekuderedza ruzha, kudedera, uye kushushikana. Chinyorwa chino chinokurukura maverengero akakosha uye zvinhu zvinofanirwa kufungwa nezvazvo pakugadzira profile yemazino egiya rakagadziriswa.

1. Chinangwa cheKuchinja Mbiri Yezino

Kugadziriswa kweprofile yemazino kunonyanya kuitwa kuti kugadzirise kutsauka kwekugadzirwa, kusarongeka zvakanaka, uye kukanganisika kwe elastic pasi pemutoro. Zvinangwa zvikuru zvinosanganisira:

- Kuderedza zvikanganiso zvekutumira

- Kuderedza ruzha rwegiya uye kudedera

- Kuvandudza kugoverwa kwemutoro

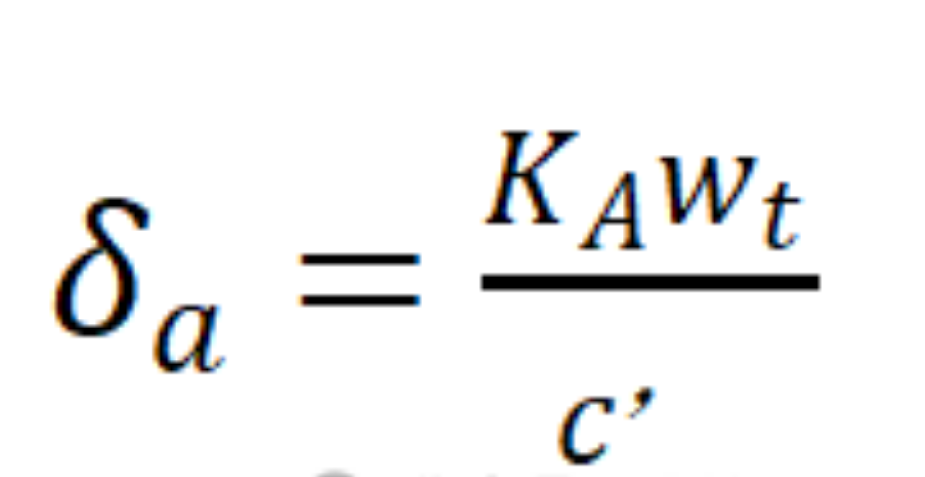

- Kuwedzera hupenyu hwegiya. Zvichienderana netsananguro yekuomarara kwegiya, kushanduka kwemazino egiya kunogona kuverengerwa nenzira inotevera: δa – kushanduka kwemazino e elastic, μm; KA – Shandisa chinhu, tarisa ISO6336-1; wt – mutoro pa unit ye upamhi hwezino, N/mm,wt=Ft/b; Ft – simba re tangential pagiya, N; b – upamhi hwezino hunoshanda, mm; c '- kuomarara kwemeshi yezino repair imwe chete, N/(mm·μm); cγ – Kuomarara kwemeshi ye avhareji, N/(mm·μm).Giya reSpur

Giya reBevel

- Rubatsiro rweZano: Kubvisa zvinhu kubva kumucheto kwezino regiya kudzivirira kukanganiswa panguva yekuisa meshi.

- Rubatsiro rweMidzi: Kugadzirisa chikamu chemidzi kuti kuderedze kushushikana uye kuwedzera simba.

- Kutukwa korona: Kuisa kakombama kadiki pahupamhi hwezino kuti zvikwanise kusarongeka zvakanaka.

- Kugadzwa korona paProfile: Kuunza kutenderera kwemupendero we involute kuderedza kushushikana kwekubatana kwemupendero.

3. Kuverenga Kwekugadzira

Kugadziriswa kweprofile yemazino egiya kunowanzo verengerwa uchishandisa nzira dzekuongorora, simulations, uye kuyedza kusimbisa. Zvinotevera zvinotariswa:

- Huwandu hweKuchinja (Δ): Kudzika kwechinhu chinobviswa pamusoro pezino, kazhinji kunobva pama microns mashanu kusvika makumi mashanu zvichienderana nemamiriro emutoro.

- Chinhu Chinogovera Mutoro (K): Inoona kuti kumanikidzwa kwekubata kunoparadzirwa sei pamusoro pezino rakagadziriswa.

- Chikanganiso Chekutumira (TE): Zvinotsanangurwa sekutsauka kwekufamba chaiko kubva pakufamba kwakakodzera, zvichideredzwa nekushandurwa kweprofile kwakagadziridzwa.

- Kuongorora Kwezvinhu Zvakakwana (FEA): Inoshandiswa kutevedzera kugoverwa kwekushushikana uye kusimbisa shanduko dzisati dzagadzirwa.

4. Zvaunofanira Kufunga Nezvekugadzira

- Mamiriro Ekutakura: Huwandu hwekuchinja hunoenderana nemutoro washandiswa uye kutsauka kunotarisirwa.

- Kushivirira Kwekugadzira: Kugadzira nekukuya nemazvo zvinodiwa kuti pave nekushandurwa kwaunoda.

- Zvivakwa zveZvinhu: Kuoma uye kusachinjika kwezvinhu zvegiya zvinopesvedzera kushanda kwekugadzirisa chimiro.

- Nzvimbo Yekushanda: Mashandisirwo ekumhanya zvakanyanya uye ane mutoro wakawanda anoda kugadziriswa kwakanyatsojeka.

5. Kugadziriswa kweprofile yemazino kwakakosha pakuvandudza mashandiro egiya, kuderedza ruzha, uye kuvandudza kugara kwenguva refu. Kugadziriswa kwakagadzirwa zvakanaka, kunotsigirwa nekuverenga nemazvo uye simulations, kunoita kuti magiya agare kwenguva refu uye ashande zvakanaka mukushandiswa kwakasiyana-siyana.

Nekufunga nezvemamiriro ekutakura, hunhu hwezvinhu, uye matekiniki ekugadzira nemazvo, mainjiniya anogona kuita mashandiro akanaka egiya uku achideredza matambudziko ekushanda.

Nguva yekutumira: Kukadzi-11-2025