Kutsvaga zvinhu zvakakodzera zvemagiya

Pakugadzira nekugadzira magiya, zvinhu zvinoshandiswa zvinoenderana nerudzi rwegiya riri kugadzirwa uye kuti richashandiswa sei uye kupi.

Kune mhando dzakawanda dzezvinhu zvinoshandiswa muzvigadziko zvemagiya, uye chinhu chimwe nechimwe chine hunhu hwacho hwemakanika hwakanakisa uye ndiyo sarudzo yakanakisisa.Mapoka makuru ezvinhu izvi imhangura, simbi, aruminiyamu uye thermoplastics.

1. Masimbi emhangura

⚙️Rinikugadzira giyaiyo ichaiswa munzvimbo ine ngura kana kuti isingade kushandisa magineti, chisanganiswa chemhangura chinowanzova sarudzo yakanakisisa.

⚙️Ma alloys matatu emhangura anonyanya kushandiswa mumagiya ndeebrass, phosphor bronze, uye aruminiyamu bronze.

⚙️Magiya anowanzogadzirwa nesimbi yemhangura ndeayamagiya ekuspiranemaraki uye zvichashandiswa munzvimbo dzine mutoro wakaderera.

⚙️Bronze yephosphor inovandudza kuramba kwekupfekwa uye kuomarara kwe alloy. Kupisa kwakanyanya uye kuramba kwekupfekwa kunoita kuti phosphor bronze alloys ive sarudzo yakanaka kune zvikamu zvinofambisa kukweshana kwakanyanya. Muenzaniso:zvishandiso zvehonye

⚙️Bhuronzi reAluminium ndiro rechitatu rinoshandiswa mukugadzira magiya. Magiya ebhuronzi eAluminium ane simba rekupfeka rakanyanya kupfuura magiya ebhuronzi ephosphor uye ane simba rekuramba kukora. Magiya anowanzogadzirwa kubva muaruminiyamu anosanganisira magiya ehelical (helical gears) nemagiya ehonye.

2. Zviumbwa zvesimbi

⚙️Kanadhizaini yegiyainoda simba guru rezvinhu, simbi dzakasanganiswa ndiyo sarudzo yakanakisisa. Kana iri mbishi, simbi grey inogona kukandirwa yogadzirwa nemagiya.

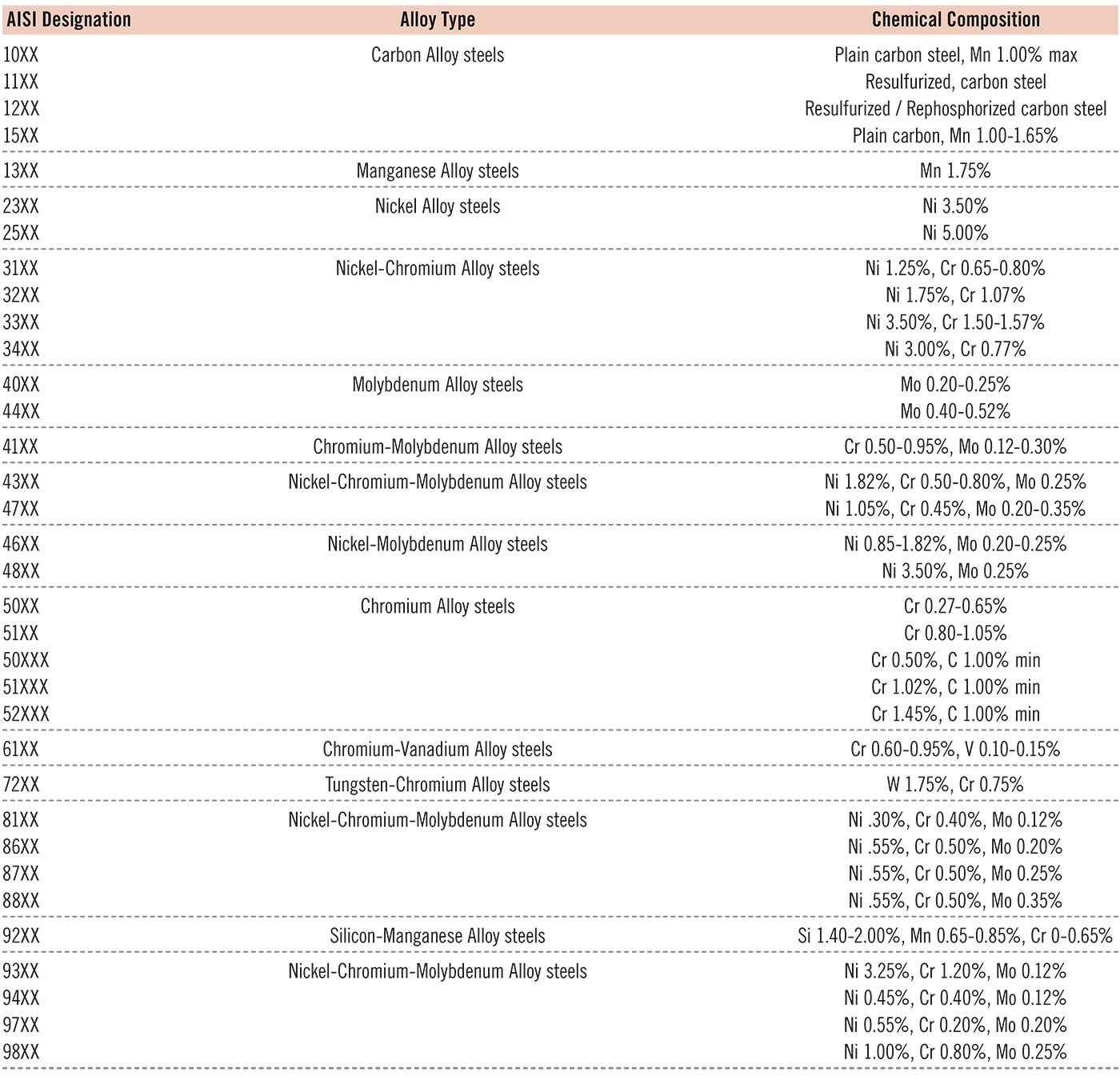

⚙️Kune mazita mana makuru esimbi alloy: simbi yekabhoni, simbi yealloy, simbi isingatsvi, uye simbi yezvishandiso. Carbon-steel alloys inoshandiswa kune marudzi ese egiya nekuti iri nyore kugadzira, haipfeki zvakanaka, inogona kuoma, inowanikwa zvakanyanya, uye haina kudhura zvakanyanya.

⚙️Masimbi esimbi yekabhoni anogona kuiswa muzvikamu zviviri: simbi isina kabhoni yakawanda, simbi ine kabhoni iri pakati nepakati, uye simbi ine kabhoni yakawanda. Masimbi asina kabhoni yakawanda ane kabhoni iri pasi pe0.30%. Masimbi ane kabhoni yakawanda ane kabhoni iri pakati nepakati kupfuura 0.60%, uye simbi dzine kabhoni iri pakati nepakati dziri pakati nepakati. Masimbi aya akanakira kushandiswamagiya ekuspira, magiya ehelical, magiya ekugadzirisa,magiya ebhevel, nehonye.

3. Zvishongo zvearuminiyamu

⚙️Ma alloy ealuminium akanaka pane alloy esimbi mumashandisirwo ayo anoda simba rakawanda-kusvika-huremu. Kupedzisa kwepamusoro kunozivikanwa sepassivation kunodzivirira alloys ealuminium kubva mukuoxidation uye ngura.

⚙️Ma alloy ealuminium haagone kushandiswa munzvimbo dzinopisa zvakanyanya sezvo anotanga kuora pa400°F. Ma alloy ealuminium anoshandiswa mukugadzira magiya ndeaya 2024, 6061, uye 7075.

⚙️Ma alloy ese matatu earuminiyamu anogona kugadziriswa nekupisa kuti awedzere kuomarara kwawo. Magiya akagadzirwa nearuminiyamu anosanganisiramagiya ekuspira, magiya ehelical, magiya ebhevel emazino akatwasuka, uye magiya ekugadzirisa.

4. Thermoplastics

⚙️Thermoplastics ndiyo sarudzo yakanakisisa yemagiya apo huremu ndiyo inonyanya kukosha. Magiya akagadzirwa nemapurasitiki anogona kugadzirwa semagiya esimbi; zvisinei, mamwe mathermoplastics akakodzera kugadzirwa kuburikidza ne injection molding. Imwe yeinjection molded thermoplastic inowanzoshandiswa injection iacetal. Izvi zvinozivikanwawo se (POM). Magiya anogona kugadzirwa kubva kune chero polymer. Izvi zvinogona kuitwamagiya ekuspira, magiya ehelical, mavhiri ehonye, magiya ebhevel, uye magiya ekugadzirisa.

Nguva yekutumira: Chikunguru-13-2023